CHAPTER 34 Techniques for Artificial Insemination of Cattle with Frozen-Thawed Semen

In the modern commercial dairy herd, management of the artificial breeding program is a major responsibility. It requires constant attention and expertise by personnel responsible for semen handling and insemination. Whether the responsibility is contracted to a professional artificial insemination (AI) technician or is assigned to employees of the farm, the requirements for success are the same. The artificial breeding program depends on the inherent fertility, health, nutrition, and management of both the cows and the bulls, as well as on the ability of the handlers to preserve, store, and deliver an adequate dose of viable semen to the cow at the proper time during the estrous cycle.

SEMEN TANK MANAGEMENT

To ensure maximum holding time, the tank should be kept in a cool and dry location away from direct sunlight, in a clean and well-ventilated area. The tank should be located in an area where it can be observed frequently to detect excessive nitrogen evaporation and development of frost around the outside neck of the storage tank. Drafts from milk coolers and furnaces should be avoided, but ventilation should be sufficient to prevent possible user suffocation, which can be caused by too high a proportion of nitrogen gas in the air. The tank should be protected from corrosion by being elevated above concrete or wet floors. A wooden dolly equipped with wheels so that it can be moved easily is ideal for tank storage. The tank should be located where it will be safe from children and vandals or locked to secure and protect semen. Particular attention must be paid to the neck and vacuum fitting. Accumulation of frost on these fittings indicates that the vacuum insulation has been lost and liquid nitrogen has been evaporating rapidly. If frost build-up is observed, a functional tank must be located and the semen transferred to it immediately. The viability of semen in the tank should be evaluated before extensive use.

Storage of Frozen Semen

Maintenance of low temperatures is important to the successful storage of frozen semen. In 1957, Van Demark and coworkers1 compared the motility of semen frozen to and stored at −79° C, −65° C, −51° C, −37° C, and −23° C. After 1 day of storage, the motility of semen stored at −37° C and −23° C was basically zero. Semen stored for 1 day at 79° C had 38% motility, compared with 29% and 14% motility for 65° C and 51° C storage, respectively. In studies in which −79° C storage was compared with −96° C2 or −92° C and −196° C 79° C was inferior to the lower temperatures when judged by maintenance of sperm motility as measured on thawing.

The reasons that subzero temperatures of −79° C and above cannot adequately preserve sperm are unclear and probably are quite complex. Rapatz,2 however, has proposed that rearrangement in the crystalline structure of frozen semen (recrystallization) may be one cause. This phenomenon has been observed to occur in frozen semen down to a temperature of −80° C. Below −80° C the structure of ice is more stable, and below −100° C it is very stable. Although no direct evidence exists for recrystallization, a correlation has been found between storage injury of spermatozoa and recrystallization.

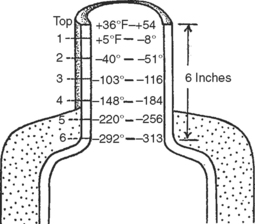

In addition to the obvious error of permitting a liquid nitrogen storage tank to go dry, stored semen also may be exposed to adverse high temperatures when straws are being removed for thawing. Figure 34-1 shows the temperature gradient that exists in the neck of a typical liquid nitrogen storage tank. As may be noted, dangerously high temperatures prevail in the upper third of the neck of the tank where canes and goblets are raised for removal. When straws are exposed to these temperatures the semen temperature rises quickly. The thermal response of semen in 0.5-ml straws exposed to temperatures of −22° C (2 inches from the top of the tank) and 5° C (1 inch from the top of the tank) is shown in Figure 34-2. The time required to reach −100° C to −80° C, which is the beginning of ice recrystallization, is approximately 10 to 12 seconds for both temperatures. Thermal injury to sperm is permanent and cannot be corrected by returning semen to the liquid nitrogen. For optimal maintenance of sperm viability, canisters and canes containing semen should be raised into the neck of the tank only for the time required to retrieve a single straw. This time should not exceed 5 to 8 seconds.

Fig. 34-1 Temperature range found in the neck of the semen storage nitrogen tank.

(From Saacke RG: Concepts in semen packaging and use. Proceedings of the Eighth Conference on Artificial Insemination in Beef Cattle of the National Association of Animal Breeders, 1974, p 15.)

Stay updated, free articles. Join our Telegram channel

Full access? Get Clinical Tree