Chapter 2 Dental Equipment and Care

SELECTING THE APPROPRIATE DENTAL DELIVERY SYSTEM

After reviewing your own practice situation and goals, the equipment suited to your practice should become more apparent. The purchase of dental equipment provides an excellent return on investment.1 The dental service is one of the most cost-efficient departments in the veterinary hospital.

Basic Oral Surgery

• A combination of various sized luxators; a set of winged elevators, with or without small, medium, and wide elevators for extractions; small, medium, and large, left and right pennant-shaped elevators.

• Burs: size 699L, 701L, 701LS, 702, #2, #4, #6, #8. Diamond burs for round burs are beneficial for bone removal and alveoloplasty.

POWER EQUIPMENT

• When purchasing power equipment, the practitioner should consider the cost of the unit, intended location for the compressor and dental consoles, noise levels at the location, availability at the clinic for equipment maintenance, and present and future dental caseload.

Features to Consider

Accessories

• Prophy angles are used to polish during prophylaxis, restorations, and other times when abrasives are used.

Electric Motor Handpieces

Comments

• Speed range 3,000 to 30,000 rpm; with accelerating contra angles speed can be increased to 125,000 rpm. (These contra angles are expensive.)

Air-Driven Power Equipment

Comments

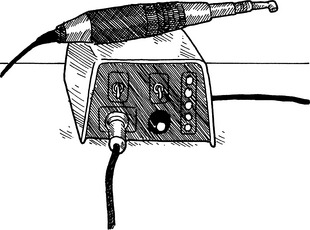

• Air-driven systems have three components: the air power source; the tubing, hoses, connectors, and controls; and the handpieces. They can be powered safely by an air compressor or by a tank of compressed carbon dioxide or nitrogen. Compressors are rated by horsepower (hp) and the ability to deliver a flow of air. Most dental handpieces require the compressor to maintain 30 to 40 pounds per square inch (psi) at a flow of 3 cubic feet per minute at the handpiece. The control section is an array of air and water switches, regulators (valves), and hoses that control the flow of air and water into the hoses and, in turn, into the handpieces. The control section can be a mobile stand, cart, wall-mounted extension arm, over-the-patient delivery system, or small countertop unit.

Advantages

• Less torque than electric motor–driven systems and therefore less heat created at the cutting surface.

• Air-driven units generally come with an air and water syringe built into the unit that is used to provide irrigation and cooling, air drying, or both, improving visualization during dental procedures.

Variable Features

Air rheostat controls

Comments

• The compressor is turned on and off by a preset pressure switch and runs only to fill the storage tank

• Compressors of less than ¾ hp are running more than they are off. This leads to overheating and temporary shutdown.

Remote compressors

Advantages

• Many smaller, table-side compressor control units without compressors are compact, can be moved around, can be used at different locations, and can be stored out of the way.

Oil-free versus oil-containing compressors

“Whisper-quiet” compressors

Comments

• Very quiet refrigerator compressors have been converted from pumping refrigerator coolant to pumping air.

• The single-unit compressor rates around ½ hp. If multi-station use or a sonic scaler handpiece is being considered, a double-unit 1-hp compressor should be considered.

Air-Driven Alternatives Other Than by Air Compressor

Nitrogen

Compressor Maintenance

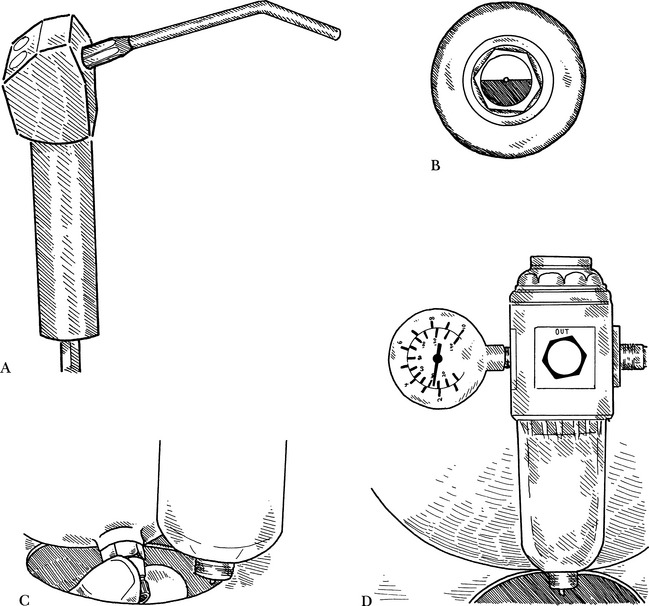

• All compressors with air storage tanks require periodic drainage of condensation from the tank (Fig. 2-2, C).

Compressor Accessories

• Filters to filter out oil and water from the compressed air. These provide for drier air and less chance of bonding material failures

Handpieces

• Handpieces enable the operator to work on teeth. They hold the mechanical cutting and finishing instruments used to modify tooth structure

• Many types of handpieces are available, and they can be categorized into three basic types: low-speed, high-speed, and sonic scalers.

General maintenance

• A handpiece should never be turned on without a bur or “blank” inserted into the chuck to prevent damage to the chuck

Low-speed handpieces

Comments

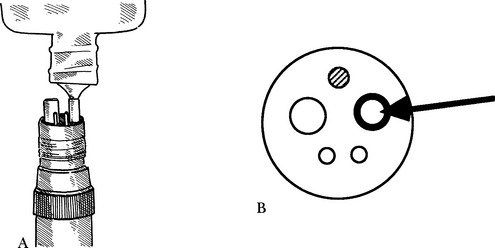

• Low-speed air-driven handpieces operate within 5,000 to 20,000 rpm. Low-speed handpieces have two kinds of connections with the contra angle, E-type and Doriot-type

• The E-type handpiece has a quick release, pull-off end for E-type prophy and contra-angle nose cones (Fig. 2-4).

Disadvantages

• Low speed is a disadvantage when drilling into or sectioning teeth; increases working time and tissue heat

• May create thermal injury because of the slow speed and pressure between the bur and tooth surface (drilling pressure).